Frequently Asked Questions

How to bleed the brake lines when installing hydraulic brakes?

- Secure the brake to the backing plate on the axle.

- Put your hub back onto the spindle.

- Tighten the castle nut, install the cotter pin, and put the dust cap back on.

- Attach the brake line to the back of the brake assembly.

- (It is best to do this with two people) Open the bleeder, apply pressure to the tongue of the trailer, and then close the bleeder.

- You should have all of the air out of the line, leaving only brake fluid.

Wheel Installation Frequently Asked Questions

How should I torque the wheels?

Using a star pattern in the correct lug nut tightening sequence. See image below.

We get questions about torque often. To best prevent your wheels from coming loose, it’s important to install the wheel correctly by tightening the bolts in the correct lug nut tightening sequence. Always follow the proper procedures and use the recommended torque specifications when installing your wheels.

Should I use a lubricant?

No. Keep it Dry. Never use lubricants. For proper torque wheel nuts, studs and mounting surfaces should be clean and dry.

What is my Lug Nut Tightening Sequence?

This is based on your bolt Pattern. See Below.

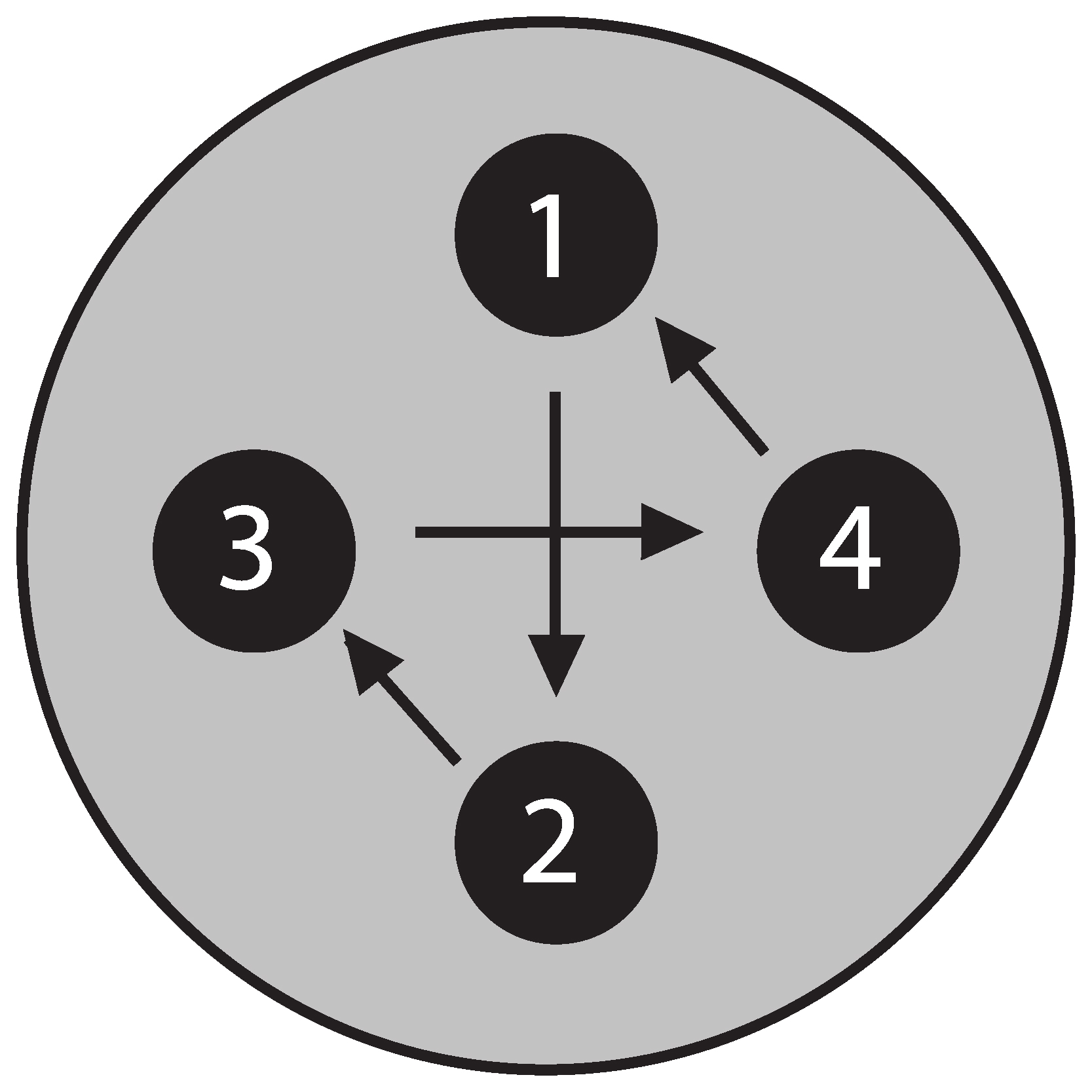

4 BOLT

Lug Nut Tightening Pattern

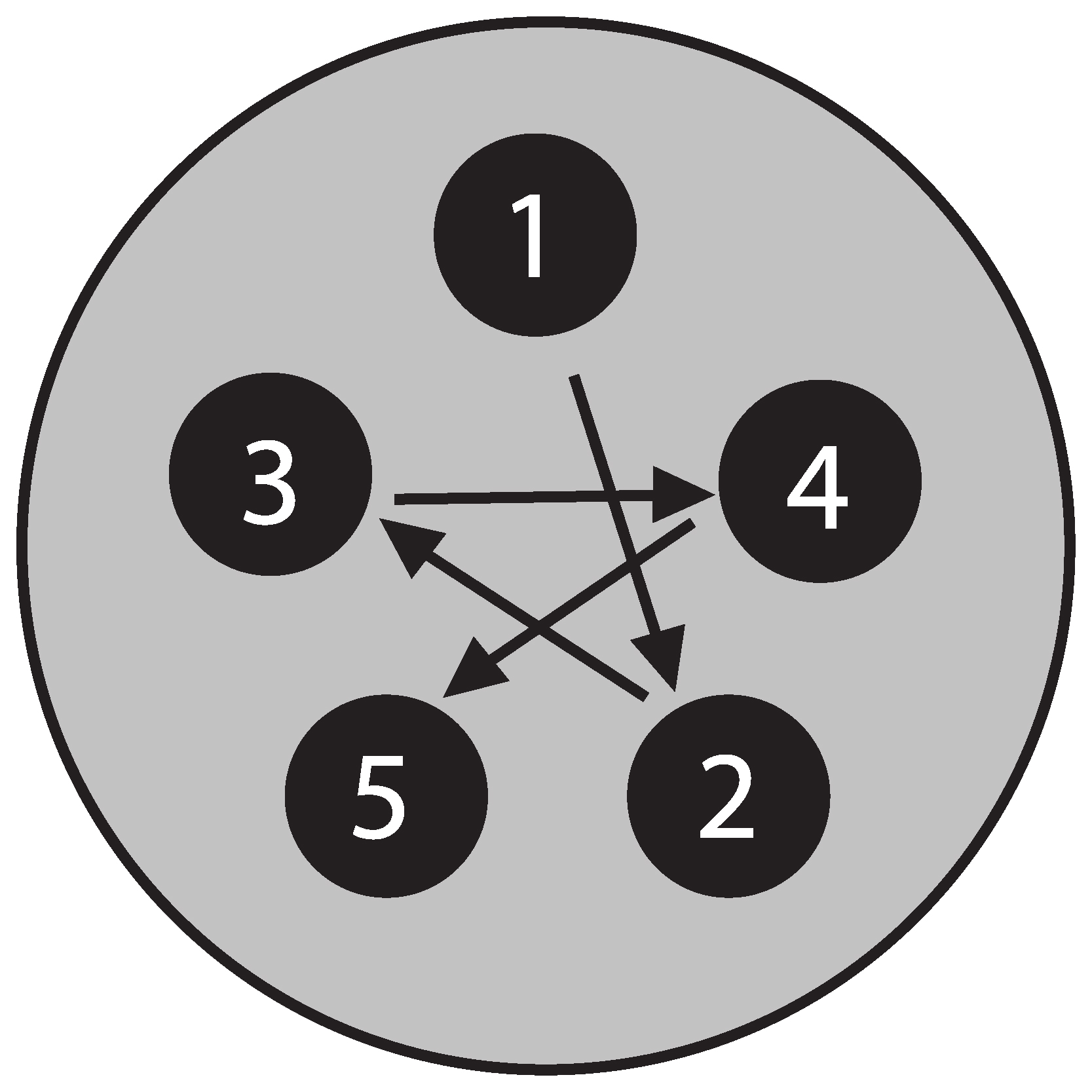

5 BOLT

Lug Nut Tightening Pattern

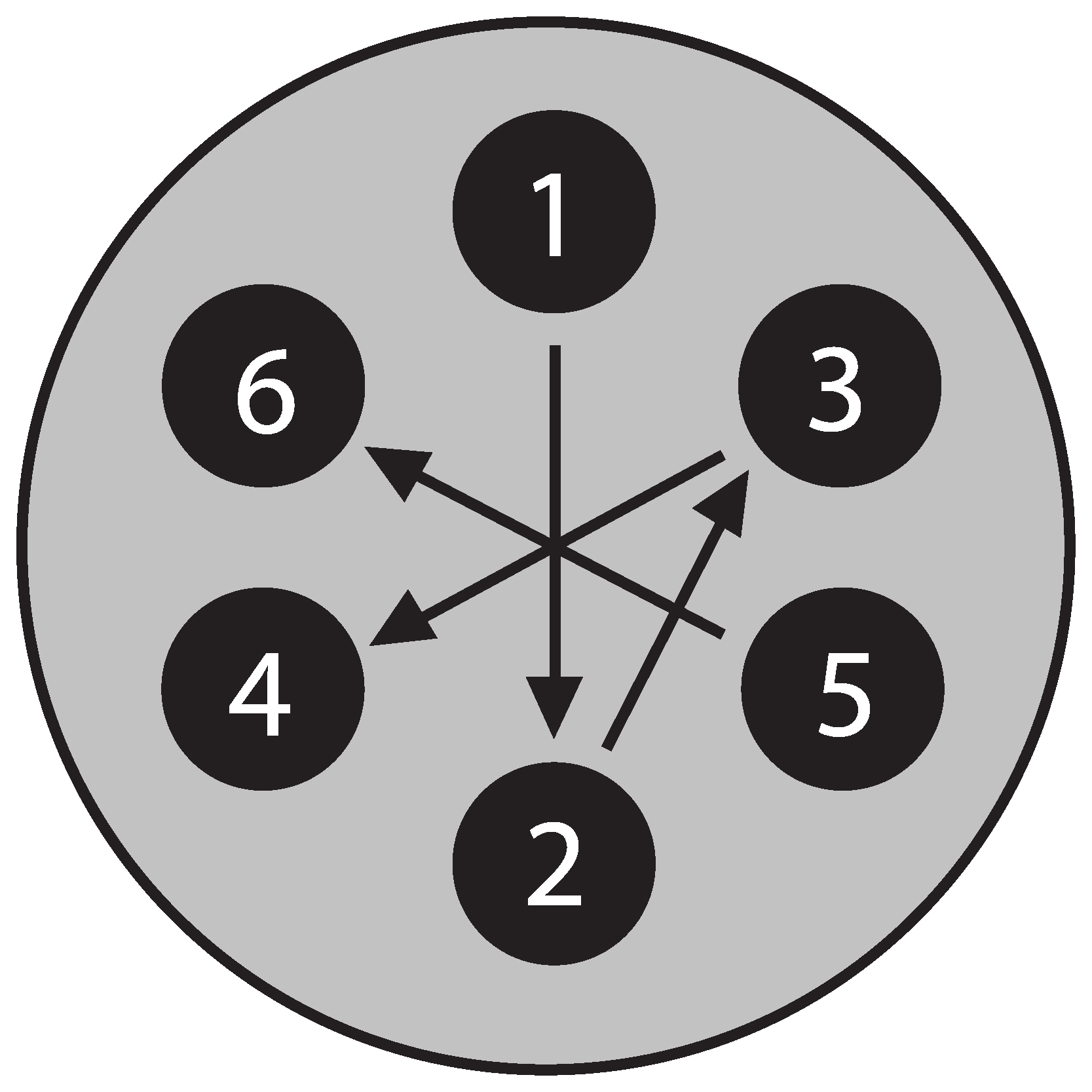

6 BOLT

Lug Nut Tightening Pattern

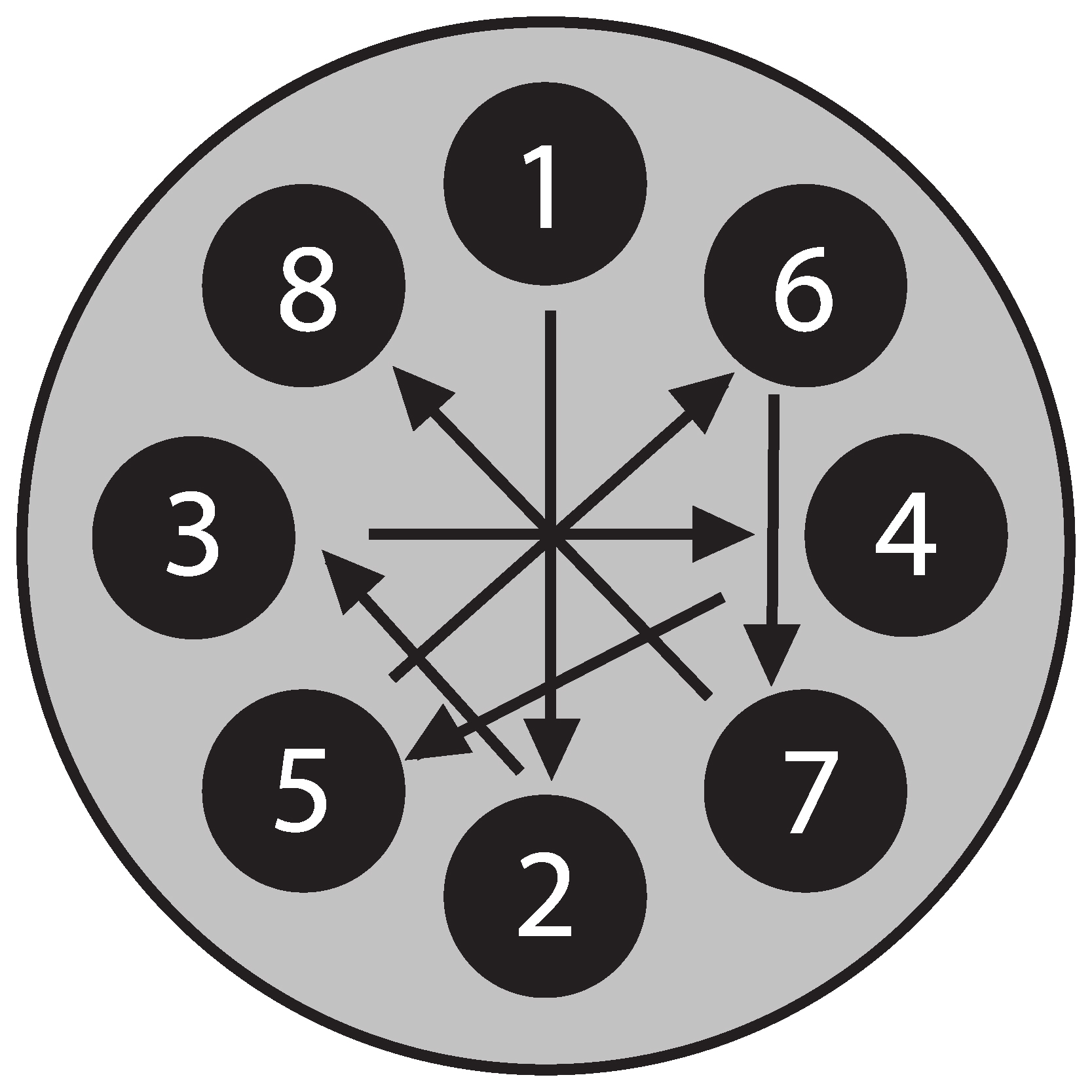

8 BOLT

Lug Nut Tightening Pattern

What is the correct lug nut tightening sequence?

Lug Nut Tightening Steps:

- Hand tighten all lug nuts using a star pattern.

- Next, tighten all lug nuts to approximately 1/2 specification using the same star pattern.

- Tighten all lug nuts to full specification using the star pattern.

- Check torque after the first trip or 50 miles, whichever comes first.

Note: If the wheel is not a 5-Bolt wheel, then use the proper tightening pattern listed in the image above.

Note: Keep it Dry. Never use lubricants or penetrating fluids, for proper torque wheel nuts, studs and mounting surfaces should be clean and dry.

When should I tighten the lug nuts?

- After installation. Check torque after the first trip or 50 miles, whichever comes first.

- Periodically. Check torque regularly when refueling.

- Rust Signs. If you spot rust on the wheel, this indicates a loose lug nut.

The twisting and turning of your trailer will cause more stress than a normal automotive wheel and the lug nuts can work themselves loose over time. Periodically check the torque and watch for red rust coming from between the lug nut and wheel which is a sign of them loosening up.

| Stud Size | Lug Nut Type | Torque Specifications | Wheel Size & Type | Wheel Material |

|---|---|---|---|---|

| ½” | Coned | 90-120 ft. -lb. | 15” | Steel |

| ½” | Coned | 90-120 ft. -lb. | 16” | Steel |

| 9/16” | Coned | 120-140 ft. -lb. | 16” | Steel |

| 5/8” | Coned with Wheel Clamp Ring | 190-210 ft. -lb. | 17.5” Single or 16” Dual | Steel |

| 5/8” | Flanged Nuts (Non-Rotating Flange) | 275-325 ft. -lb. | 17.5” Single or 16” Dual | Steel |

| 5/8” | Flanged Nuts (Rotating Flange) | 190-210 ft. -lb. | 17.5” Single or 16” Dual | Steel |

| ½” | Coned | 90-100 ft. -lb. | 15” | Aluminum |

| ½” | Coned | 90-100 ft. -lb. | 16” | Aluminum |

| 9/16” | Coned | 120-140 ft. -lb. | 16” | Aluminum | 9/16” | Coned | 130-150 ft. -lb. | 17.5” | Aluminum | 5/8” | Coned | 140-160 ft. -lb. | 17.5” | Aluminum | 5/8” | Flanged Nuts (Rotating Flange) | 150 ft. -lb. | 16” | Aluminum |