Are you dealing with a broken camper suspension system or one that needs an upgrade? The first step to working on a camper’s suspension is understanding its system components and how they work together. The suspension system underneath a camper determines its load-bearing capacity and ability to go off-road, as well as other variables.

Not every camper has the same type of suspension system, but every system needs regular maintenance and occasional repair. Preventive care can help a suspension system last longer so its owner can enjoy many adventures for minimal expense. Here’s more about camper trailer suspension systems and how to maintain them.

What Are Camper Trailer Suspensions?

A suspension system supports a trailer’s weight and creates a smoother ride experience, especially on uneven ground. There are different kinds of suspension systems, but they are all designed to absorb impacts, keeping them from traveling into the frame. Here are two types of suspension you should know about:

- Independent suspension: This design allows each wheel to move independently. Torsion axles are a type of independent suspension.

- Solid axle suspension: By contrast, solid axle suspension connects wheels with a solid axle. The wheels on each side of a vehicle impact each other. Spring axles use solid axle suspension.

Over time, the suspension system under a camper trailer will lose grease and spring tension. Metal parts may rust and corrode, losing their strength and reliability. Although maintenance can help extend the life of a suspension system, eventually, you’ll need to replace part or all of a suspension setup for the best trailer performance.

Types of Camper Trailer Suspension Systems

Common mechanisms for trailer suspension systems include spring axles, torsion axles and independent trailer suspensions. These mechanisms can be used for independent and solid axle suspensions. Each suspension system has advantages and disadvantages for camper trailers.

Straight Spring Axles

This kind of trailer suspension is made with metal leaf springs, and they’re only paired with a solid axle suspension system. The advantages of spring axles for camper trailers include their simple design, durability and high load capacity. Straight spring axles are also less expensive than other types of suspension systems.

However, spring axles cause a bumpy ride compared to independent suspension systems. They don’t handle uneven terrain as well and require maintenance to reduce squeaking from metal parts rubbing together. Because they pair with a solid axle suspension, they have less stability on uneven surfaces.

Torsion Axle

Torsion axle systems use rubber cords inside the axle to suspend a trailer. They are a type of independent suspension system unlike spring axles. Some benefits of using a torsion axle suspension are suitable ground clearance, quiet operation and low maintenance. Torsion axles are independent, so each wheel can react to uneven ground on its own, handling rough terrain well.

Some downsides to using a torsion axle system include a lower load capacity than spring axle systems. Although it requires less maintenance, this kind of suspension is also more expensive upfront. Overloading a camper with torsion axles can lead to “bottoming out,” or when the suspension reaches the end of its travel and can damage the axle.

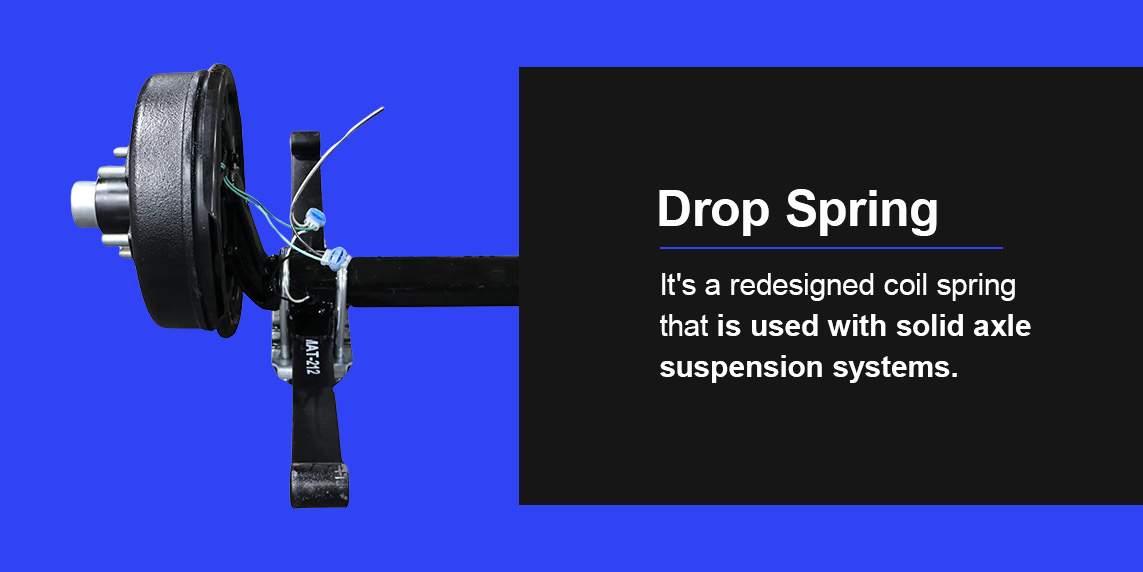

Drop Spring Axles

This kind of suspension system lowers a trailer’s ride height. It’s a redesigned coil spring that is used with solid axle suspension systems. Some advantages of drop spring axles include stability from a lower center of gravity and easier loading and unloading of camping gear.

However, drop axles mean the camper is lower to the ground and has less clearance for off-roading. Lowering the trailer could lead to issues with the axle hitting the other components and getting damaged, so drop spring axles aren’t a common choice for camper trailers.

Key Components

Trailer suspension systems are made of several key components, most of which can be replaced independently of each other. Here are some of the most common parts of suspension systems:

- Axles: Types of axles include straight axles, torsion and 4″ drop spring axles.

- Axle hangers: Brackets that connect leaf springs to a trailer frame.

- Bushings: These parts are often made of rubber. They reduce friction and absorb vibrations.

- Springs or cords: Straight spring axles use leaf springs, while torsion axles need rubber cords.

- U-bolts: These bolts clamp leaf springs to the axle.

Different types of suspension systems use different combinations of parts. Regardless of the system on your trailer, you’ll also need plenty of clean grease or oil to keep everything moving smoothly.

How Often Do Suspension Parts Need to Be Replaced?

Suspension parts wear out at different rates, depending on how often your trailer is used, the climate where you live and other factors. The best way to determine whether your suspension parts need to be replaced is with regular inspections.

If you can visibly see damage, it’s time for a replacement. Having to replace pieces of a suspension system repeatedly can also be a sign that your trailer could use a completely new system. Loud noises and uneven tire wear are other signals that something isn’t right with your suspension.

Maintenance Tips for Camper Suspensions

Regular maintenance is essential for a durable suspension system and reduced repair costs. Here are several maintenance steps camper trailer owners should take to protect their suspension:

- Inspect components. A visual check can help catch problems early. Before and after using your camper, take a minute to look over it and check that everything looks right.

- Lubricate parts. Make sure bushings and joints are well-greased to reduce friction.

- Monitor tire wear. Are the tires wearing down unevenly? If so, the trailer’s alignment may be off. One way to fix tire alignment is by getting a new axle.

- Upgrade old parts. If any components are rusty or bent, replace them to avoid further damage. Rust will spread over time, so an early fix can save you repair costs.

- Schedule regular inspections. Especially before long trips, a camper inspection can help locate potential problems and make sure it’s in good condition.

Camper suspension maintenance can save trailer owners costs down the road. Eventually, parts wear down and need to be replaced. By catching and fixing these issues early, trailer owners can enjoy their campers with minimal maintenance and repair costs.

Get New Axles From BlueSwift Axles

At BlueSwift Axles, we provide axle replacement, trailer parts and repair kits. If your axles are twisted, rusted or broken, you shouldn’t have to wait weeks to replace them. We can build new axles in as little as 48 hours so you can get your customers or yourself back on the road ASAP.

Axle types we offer include:

If you have any questions about measuring or ordering your axle, give us a call! We also offer parts for trailer suspension, jacks, wheels and more. Check out our FAQ page to learn more about axles, and call us today for a quote.