Can I Replace My 3,500 lb Axle with a 5,200 lb Axle?

Upgrading your trailer’s axle is one of the best ways to boost strength, safety, and long-term reliability. Many trailer owners ask whether they can replace a 3,500 lb axle with a 5,200 lb axle — and the answer is yes, it’s possible with the right planning and parts.

However, it’s not as simple as bolting on a new axle. A few key differences affect how the upgrade fits and performs. You’ll gain significant durability and braking power, but you’ll also need to account for changes in hub patterns, wheel compatibility, and spindle length.

Let’s break it all down so you can decide if upgrading to a 5,200 lb axle is the right move for your trailer.

Understanding the Difference Between 3,500 lb and 5,200 lb Axles

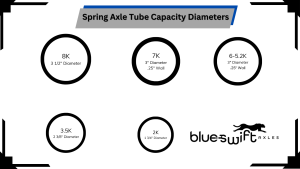

A 3,500 lb axle is one of the most common sizes used on light- and medium-duty trailers. It’s ideal for small utility, landscape, and camper trailers. These axles typically feature a 2-3/8” outer diameter axle tube with a 3/16” wall thickness.

When you move up to a 5,200 lb axle, you’re entering a heavier-duty category. The 5.2K axle uses a 3” outer diameter tube with a 1/4” wall thickness. That thicker, larger tube dramatically increases strength, reduces flex under load, and helps your trailer handle rough roads or heavy cargo without bending or fatigue.

In short:

-

3.5K axle: 2-3/8” OD, 3/16” wall thickness

-

5.2K axle: 3” OD, 1/4” wall thickness

This difference gives you more confidence when towing at higher weights or on uneven ground. The heavier wall also resists torsion stress better, helping your axle last longer under tough use.

Brake Upgrade: 10×2-1/4″ vs. 12×2″

When you upgrade from a 3,500 lb axle to a 5,200 lb axle, your brake size jumps as well.

A standard 3.5K axle uses 10” x 2-1/4” electric brakes, while a 5.2K axle steps up to 12” x 2” brakes. This change matters — larger brakes mean more stopping surface, better heat dissipation, and shorter stopping distances when hauling heavy loads.

If you’re pulling equipment, enclosed, or tandem-axle trailers, that extra braking power provides a major safety improvement. You’ll feel a smoother, more controlled stop, especially on downhill grades or during emergency braking.

Hub and Wheel Pattern Changes

Here’s where many people get caught off guard.

Most 3,500 lb axles come with 5-bolt hubs. When you move up to a 5,200 lb axle, the hub pattern switches to 6 bolts. That means your old wheels will not fit the new hubs.

You’ll need to upgrade to 6-lug wheels to match the new bolt pattern. The benefit is that 6-lug wheels are built for higher load ratings and use larger bearings and races to match the bigger spindle on a 5.2K axle.

So, when you make the switch, expect to buy:

-

New 6-lug hubs and drums (included with most 5.2K axle kits)

-

New 6-lug trailer wheels if your old ones are 5-lug

The upside: the larger bearings and spindles give you more durability and longer bearing life — perfect for trailers that see a lot of miles or carry heavy cargo.

Spindle and Bearing Differences

One of the biggest mechanical upgrades between a 3.5K and a 5.2K axle lies inside the hub.

A 3,500 lb axle typically uses an L68149 inner bearing and an L44649 outer bearing. A 5,200 lb axle steps up to a larger 25580 inner bearing and LM67048 outer bearing, which fit over a larger-diameter spindle.

These heavier bearings handle more load and resist heat better. The spindle design also adds strength where it counts most — at the connection between your hub and axle tube.

This means you’ll get more stability and less wear during long hauls, particularly under heavy loads.

Axle Tube Cut Length and Frame Clearance

When upgrading axles, tube length and hub face spacing are critical details.

If you’re trying to match your trailer’s current hub face-to-hub face dimension, you can’t just order the same cut length tube. The 5.2K spindle is longer, which changes how far the hub sits from the frame.

Here’s what you need to know:

For Straight Spring Axles

To keep the same hub face measurement, the cut length of a 5.2K axle tube must be 2.375 inches shorter than your 3.5K axle.

That difference pushes your brake assemblies 1.185 inches closer to the trailer frame on each side. You’ll need to check your frame, tires, and brake backing plate clearance to ensure everything fits safely.

If space is tight, you may need to adjust your spring hangers or hub face to compensate.

For Drop Spring Axles

On drop axles, the overall cut length difference between a 3.5K and 5.2K axle is 2.25 inches.

This still moves the brakes slightly closer to the frame but not quite as much as on straight axles. Measure twice before ordering to make sure the fit works for your setup.

A good rule of thumb: always check your inside tire clearance, brake backing plate distance, and fender spacing before finalizing your order.

Spring Seat Location and Suspension Compatibility

When upgrading, confirm your spring seat centers match your trailer’s suspension. Spring seats determine where your leaf springs mount to the axle.

If your new 5.2K axle has different spring seat spacing, the axle won’t bolt up properly. Blueswift Axles can custom-build your 5.2K axle to match your trailer’s original spring seat and hub face dimensions.

That ensures a direct fit without cutting, welding, or re-positioning your hangers.

Weight Ratings and Safety Considerations

While upgrading your trailer axle to a 5,200 lb axle gives your trailer a stronger foundation, keep in mind that your trailer’s overall GVWR doesn’t automatically increase.

The Gross Vehicle Weight Rating (GVWR) depends on your weakest component — that includes the frame, suspension, coupler, tires, and brakes. Even with heavier axles, you must respect the original GVWR unless the manufacturer certifies the trailer for a higher rating.

That said, a heavier axle can still improve durability and reduce maintenance costs since it operates below its maximum capacity.

If your trailer often runs near the 3,500 lb axle’s limit, a 5.2K axle upgrade adds a valuable safety margin.

The Benefits of Upgrading to a 5,200 lb Axle

Upgrading your trailer axle offers several long-term advantages:

1. Stronger Axle Tube

The 3” diameter tube with a 1/4” wall thickness resists bending and fatigue. You’ll see less flex under load and better alignment over time.

2. Bigger Brakes

The 12” x 2” brakes give you noticeably better stopping power and control. That’s especially important when towing on steep grades or in heavy traffic.

3. Heavy-Duty Bearings and Spindles

Larger bearings mean more load capacity, longer lifespan, and better resistance to heat buildup.

4. Improved Ride Stability

A heavier axle reduces bounce and sway, especially on tandem-axle trailers. It feels more planted on the road.

5. Long-Term Value

The upgrade costs more upfront, but you’ll gain reliability, fewer bearing replacements, and better braking — all of which reduce downtime.

Potential Challenges to Watch For

Before committing, make sure to plan for these common challenges:

-

Wheel Compatibility: You’ll need 6-lug wheels to match the new hubs.

-

Clearance: The new spindle design pushes your brakes closer to the frame, so always measure clearance before ordering.

-

Suspension Alignment: Verify spring seat spacing to ensure a proper fit.

-

Brake Controller: Make sure your tow vehicle’s brake controller is properly rated and adjusted for the 12” brakes.

None of these are dealbreakers — they’re just part of doing the upgrade right the first time.

Installation Tips for Success

If you’re upgrading your trailer axle yourself or through a shop, follow these steps:

-

Measure Your Existing Axle:

Record the hub face-to-hub face and spring center-to-center measurements. -

Check Frame and Fender Clearance:

Ensure enough space for the new brakes and hub position. -

Upgrade Wheels and Tires:

Use 6-lug wheels rated for your trailer’s load. -

Verify Brake Wiring:

Confirm the wiring and connectors match your new 12” brake assemblies. -

Torque Everything to Spec:

Proper torque on U-bolts, lug nuts, and spindle nuts is critical for safety. -

Test Before You Tow:

After installation, perform a short test tow to confirm alignment, braking, and suspension travel.

Real-World Example

Let’s say you’re upgrading a tandem-axle utility trailer that hauls equipment. Each 3.5K axle gives you a combined 7,000 lb capacity. You’re often hauling loads close to that limit.

By switching to two 5.2K axles, you’re still limited by the trailer frame’s GVWR, but your axles now carry weight more efficiently. The trailer will ride smoother, your bearings will last longer, and your brakes will handle heat better.

It’s an upgrade that pays off over years of use — especially for contractors, landscapers, and haulers who rely on their trailers daily.

Ordering the Right Axle

When you’re ready to upgrade, have these measurements and details handy:

-

Hub face-to-hub face distance

-

Spring center-to-center distance

-

Straight or drop spindle type

-

Brake style (electric or hydraulic)

-

Wheel bolt pattern (switching to 6-lug)

At Blueswift Axles, we can custom-build your 5.2K axle to match your trailer’s specs exactly. That means you’ll get the perfect hub face, spring center spacing, and pre-welded spring seats — all ready to bolt on.

We also stock everything you need for the upgrade, including:

-

Axles (straight or drop)

-

Hub and brake kits

-

U-bolt and shackle hardware

-

6-lug wheels and tires

-

Wiring and brake controllers

Final Thoughts: Is It Worth the Upgrade?

Upgrading your trailer axle from a 3,500 lb to a 5,200 lb is more than just adding capacity — it’s about durability and control.

The 3” tube with a 1/4” wall thickness gives you a stronger foundation. The larger 12” brakes give you more confidence when stopping. The bigger bearings and spindles handle long trips and heavy use without wearing out as quickly.

The key is proper measurement and clearance planning. As long as you verify frame clearance and upgrade to 6-lug wheels, the swap can transform how your trailer performs.

If you’re ready to make the move, Blueswift Axles can help you build the perfect 5.2K axle setup — fast, affordable, and ready to bolt on.

Blueswift Axles is America’s #1 source for trailer axles and parts, proudly supplying everything from custom-built axles to brakes, hubs, suspension, and electrical components — all with the fastest lead times in the industry.

Visit blueswiftaxles.com to get started or call us today for a quote on your 5,200 lb axle upgrade.